CIE is an innovative technology company that has been committed to the exploration and innovation of plastic extruders and thermoforming machines in the fields of research and development, design, manufacturing, sales, and after-sales service. Aiming to provide customers with excellent overall solutions for the blister packaging industry, CIE has introduced advanced molding machine technology from Germany, Italy, and combined with its own years of R&D, manufacturing and application cases to continuously create high-end and efficient equipment for customers. It has been exported to many countries in the world and won unanimous praise from customers.

We work hard:

CIE has an elite R&D team. Its core members have more than 10 years of product development and design experience in related industries, and can provide customers with mature and stable overall solutions in thermoforming technology, equipment and molds. Over the years, they have served many world-renowned companies.

Our professional focus:

The CIE market operations team has been focusing on the promotion and application of plastic extrusion equipment and thermoforming automation equipment for many years. It has experience in the market expansion of international automation equipment companies and KNOW-HOW in many mainstream application industries. It has excellent capabilities and Experience enables us to more accurately grasp market trends and meet the diverse needs of customers.

We advocate technology:

We are people-oriented, truth-seeking and pragmatic, and strive for perfection. We have a complete quality control system. We adopt strict testing standards for each component of the product to ensure the overall quality of the equipment. We strive to build cutting-edge equipment in the industry and create value for customers.

Product introduction:

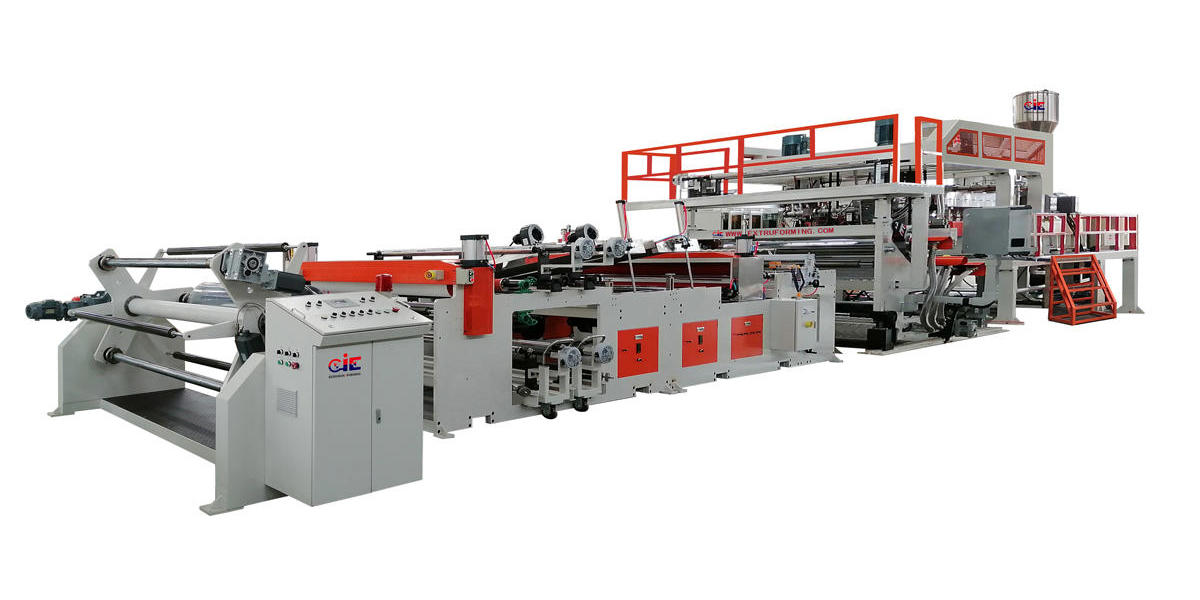

CIE-1500 PET Sheet Extruder Machine:

General Conditions of Machine: | |

Power supply: | 380V /3 phase/ 50 Hz |

| Raw Material: | APET, PETG, CPET pellets and flakes |

Sheet thickness: | 0.10 - 2.5 mm |

Net width of sheet: | Max.1550 mm |

Layer structure of sheet: | 1-layer/2-layer/3-layer |

Extruding capacity: | 450-1000kg/h |

Install/consumption of power: | 350KW/180KW |

Compressed air: | 1M3 / h, 0.6—0.9Mpa |

Cooling water: | 12M3 / h; 25℃ |

Machine size: | L22M X W5M X H3M |

Machine weight: | About 28 tons |

Containers: | Three 40’-HQ |

Control Method: | Siemens PLC 12" (touch screen Monitor) |

Applications of Sheet Made by Machine:

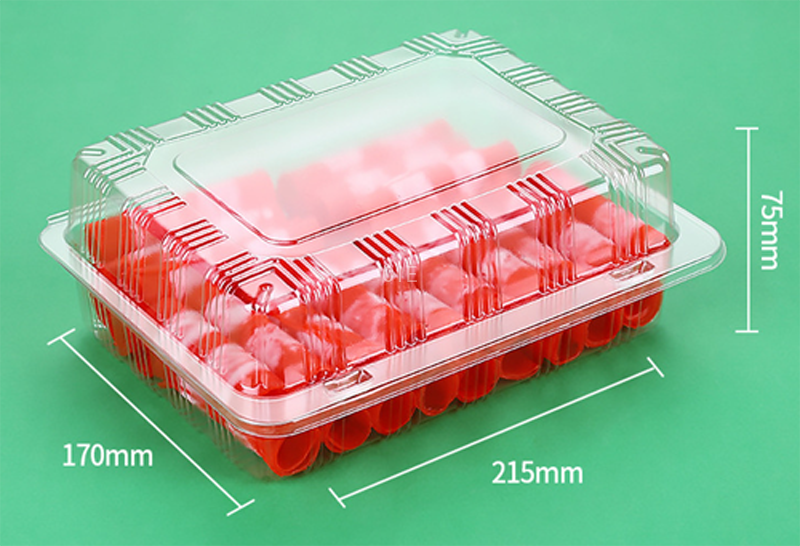

PET sheet is divided into APET, PETG, CPET and other materials, which are widely used in various packaging and

electronic industries.

For more details, please contact sales.